Hydraulic systems monitoring and maintenance must improve to keep up with rising regulatory requirements and changing equipment design.

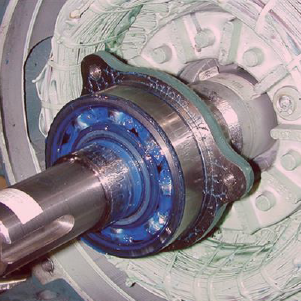

A grease-oiled bearing can be lubricated manually, automatically (semi or fully), or for the duration of the bearing's life. While many bearings are regarded as "lubed for life," many others still require grease on a regular basis. A grease gun is the most popular method of lubricating a bearing. Lever action, pistol, and grip air-powered are among the options.

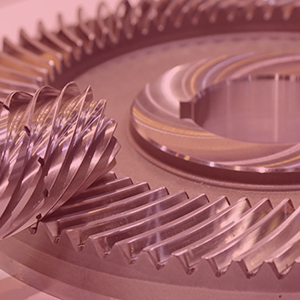

When we think about metal, it's hard to believe that it's compressible, let alone that it can recover after being compressed, much like a spring.

A single-point lubricator is a device that delivers a small amount of clean grease or lubricating oil to a specified region on a regular and automated basis. It is most commonly used to lubricate bearings, but it may also lubricate pumps, electric motors, fans, chains, and conveyors. Greasing bearings by hand frequently results in over-and under-greasing, resulting in premature bearing wear. In addition, automated lubrication allows proper lubrication of components that are too hard or risky to reach, which positively impacts reliability and safety.