Improvements in contamination control still remain in the shadows in the world of reliability. Invisible particles are one of the most significant causes of wear and tear on machinery. Lubricants are valuable assets to your company, and when handled properly, they will pay for themselves many times over.

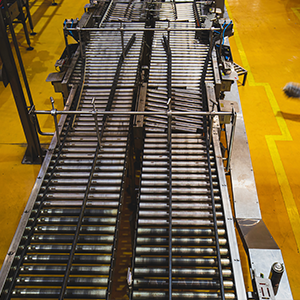

Conveyor chains are essential for productivity in a variety of industries, including mining, materials manufacturing, as well as food processing, and transportation. These chains, however, can have repeated issues and failure throughout the course of their many thousands of hours of operation.

Performance, work hours, and total uptime have all improved as a result of the new advances in lubricant products. At this moment, there are various filters available in the market of different sizes, compositions, designs, etc. Let's take a look at some of these filters.

The viscosity of a lubricant is selected based on the thickness of the film. In a bearing, this film acts as a barrier between the rolling and stationary parts. When you mix lubricants of the same type but with different viscosities, the viscosity of the lubricant will definitely change.

While the method for oil sampling varies based on the application and machine being sampled, most oil sampling equipment may be used in a variety of situations.

Vibration analysis monitors misalignment and looseness while oil analysis monitors lubricant quality, contamination, and machine wear They collaborate on root cause determination to allow easy management of the "big five" causes of machine failure.