Conveyor chains are essential for productivity in a variety of industries, including mining, materials manufacturing, as well as food processing, and transportation. These chains, however, can have repeated issues and failure throughout the course of their many thousands of hours of operation.

A conveyor lubricating system may enhance power transmission while also reducing wear, corrosion, and noise. Inadequate or interrupted lubrication can cause conveyor chains to break prematurely, halting production and requiring costly downtime.

Conveyor Lubricants

It's a major job to keep your food and beverage supply going. For food and beverage production, traditional conveyor lubricants might imply a lot of water, frequent applications, and a lot of planned downtime.

Conveyor Lubrication

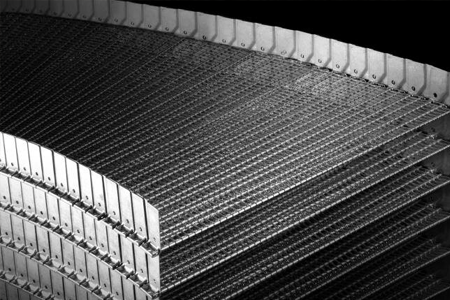

A conveyor system is a collection of belt support, pulley, drive unit, and connections that move a conveyor belt around a track. They require lubrication since they operate on a track with the aid of electrical motors. Conveyor systems may easily last 10 to 20 years with proper lubrication. Conveyor lubrication is necessary for the fluid and continuous circulation of containers in a production line, as well as for the proper operation of production and optimal productivity in the line.

The lubrication system sprays one or two droplets of lubricant onto each conveyor at a predetermined interval, forming a regular microscopic coating over the whole length of contact between the product and chain and the guides and chain. The procedure is carried out in a closed-loop, with injectors introduced throughout the manufacturing line from central units. A conveyor system's lubrication is critical. Two vital instruments are required to oil the conveyor belt's components. Conveyor belts are best lubricated either a brush-style lubricator or a high-pressure lubricator. Bearings are frequently sloppy and do not function correctly owing to a lack of lubrication.

Chain Drive Lubrication

The preferred technique of lubricating chain drives is clearly stated in the catalogs of certain conveyor systems. Manual, oil bath, oil stream, drip, and slinger disk are some of the ways that frequently appear. These ways are the most successful because gravity aids the flow of oil into the critical bearing area.

Efficient Service

A conveyor lubrication system that is correctly built and managed may increase the usable life of a chain by 100 times or more. Pins and bushings that are nearly worn through, or when elongation creates greater or unequal stresses on certain joints, are examples of terminal wear.

An inadequate or disturbed lubrication system can cause a chain to wear quickly and unevenly. Lubrication between pins and bushings minimizes wear and aids with the removal of wear particles and other debris. Conveyor belt lubrication may assist prevent corrosion, transmitting heat, and reducing impact stress. A manufacturing plant was able to achieve 50% improvement in uptime through an automatic lubrication system.

Preserving the Condition of Your Belt Conveyor

Belt conveyors are one of the most used pieces of food processing equipment. They transport everything from big product boxes to individual potato chips for frying. No conveyor is completely free of issues, from motor burnout to belt slippage or damage from wrong use. Here are useful tips in maintaining your conveyor health:

- Identify a suitable conveyor

- Keep your belt in good shape

- Maintain the motor's cleanliness

- Check your bearings

- Check the alignment and wear of your pulleys

- Examine the belt for slipping

- Check to see that the motor and drive are the correct sizes

- Examine and replace any worn components

- Preventive maintenance is essential

Le Price Conveyor Solutions

ExactaStack®

For companies looking for a cost-effective, high-quality food processing solution, ExactaStack® is an economical belt choice for regular and wide belt stackers. For both spliced-in pieces and entire belt replacements, ExactaStack is available in all widths, tier heights, and mesh combinations. Companies in the food sector rely on Ashworth to keep their operations running smoothly by incorporating ExactaStack into their manufacturing processes.

PosiDrive Spiral®

The PosiDrive Spiral® is a dependable, long-lasting system with intuitive controls for ensuring product alignment and placement for downstream processing. It may be retrofitted into current proofing, cooling, and freezing spiral systems with relatively modest design changes. The drive's design keeps belt tensions low, extending belt life and allowing for higher product load capacity.

Source: machinerylubrication.com