A production plant in Pampanga, Philippines manufactures a wide range of beverage products. This plant frequently replaced their bearings every 3 months. After the installation of the Simalube single-point lubricator, the bearing life was prolonged, production time improved, and labor cost has been noticeably reduced.

Bearing replacement has been a common practice in the production lines. The bearings were exposed to damaging elements such as dirt and water. These elements will reduce the bearing life, thus reducing the production uptime and increasing the bearing replacement cost. This had been an obvious problem for the client. Without proper lubrication, the bearings were susceptible to premature failure. When proper lubrication is neglected, machine failure is expected to follow.

Maintaining Bearing Health with Proper Lubrication Management

Before the installation of Simalube - Single Point Lubricator, the bearings were often prone to damage and frequent replacement. This manufacturing plant reached out to Le Price International Corporation and Le Price conducted a thorough assessment to determine the best solution to offer to them. Afterwards, the maintenance department of the plant approved the trial installation in February 2014. The trial installation of a single-point lubricator to the client’s conveyor center bearing came with a SystemPlast flange bearing.

The Simalube - Single point lubricator provided an efficient lubrication method for the client’s bearings or chains. This lubrication system has an adjustable dial that lets them set the number of months they want to have the lubricators release the grease or oil. This system helped them reduce maintenance costs and production downtime. The Single-point lubricator also lessens health hazards for the maintenance team. Not having to go through the dangerous parts of the equipment with a manual lubricating system, saves a lot of time, manpower, and avoids health hazards.

A 60ml Simalube cartridge was automated to be consumed for 8 months. With less labor cost and scheduling problems, the installation of a single-point lubricator was expected to cut labor costs and prolong bearing life. This system ensures the client that their bearing maintenance needs will not be neglected.

The Result

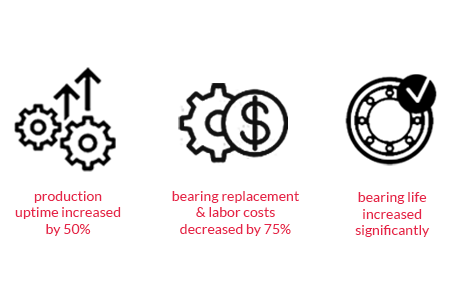

After the trial installation, the results show significant changes in bearing life, production uptime, bearing replacement cost, and labor cost. Eight months after the installation, the bearings were kept in top shape and optimal performance. The production uptime was improved by 50%, and the bearing replacement cost has been reduced by at least 75%. Lastly, the estimated labor cost was cut down to at least 75% which proved that the Simalube Single point lubricator was a big help in maintaining bearing life and performance.

After the trial installation, the results show significant changes in bearing life, production uptime, bearing replacement cost, and labor cost. Eight months after the installation, the bearings were kept in top shape and optimal performance. The production uptime was improved by 50%, and the bearing replacement cost has been reduced by at least 75%. Lastly, the estimated labor cost was cut down to at least 75% which proved that the Simalube Single point lubricator was a big help in maintaining bearing life and performance.

Solutions

Lubrication systems, there are purchase options to choose from. You may choose to set aside a capital investment or you may choose Subscription-Based Automatic Lubrication System which ensures the right amount of lubricant oil and grease at the right time, at the right place for customers' equipment, without the need for capital investment. The subscription-based automatic lubrication system includes operation and maintenance of the Automatic Lubrication System. If you are not sure which option best fits your plant requirement, you can talk to Le Price reliability engineers to help you assess the best solutions that address your problems.