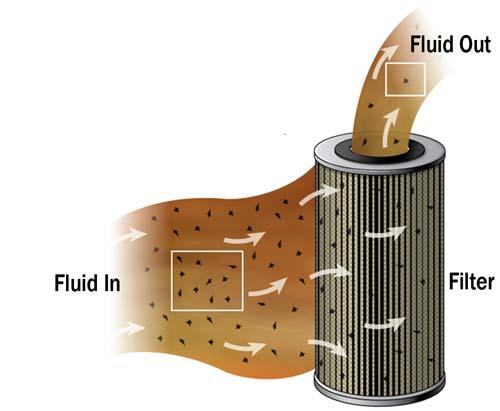

Performance, work hours, and total uptime have all improved as a result of the new advances in lubricant products. At this moment, there are various filters available in the market of different sizes, compositions, designs, etc. Let's take a look at some of these filters.

Basic Factors to Consider

Pieces of machinery have different requirements for filters. What works for an engine may not work for a hydraulic system. In addition, hydraulic filters are durable because they must withstand higher pressures and they are usually situated in the return line. On the other hand, engine (diesel) oil filters are usually situated before the critical components. Filter requirements will vary depending on your application.

Motivation for Clean Oil

Contamination was found to be one of the leading causes of 80% of bearing failures. You address contamination issues, expect cases of bearing failures to go down significantly. Maintenance professionals who use excellent filtering procedures frequently claim longer service life and lower maintenance costs. Contamination by dirt and particles can negatively impact component life span, lubricant life, and sustainability. These effects in diesel and gasoline crankcase oils on engine dependability have been extensively studied.

When Small Things Make a Big Impact

Silicon is the second most prevalent element on the planet after oxygen. It is usually found in dirt and dust. The most common way for terrain dust to enter a machine is through the air intake. Air filters that are effective may remove 99 percent or more of the dust that an engine consumes. Dust contamination of lubricating oil is typically thought to be the most detrimental to rotating components.

Millions of microscopic particles per milliliter of oil are far more than the number of big particles. Typical road dust has around 80% of its weight in particles smaller than 25 microns. The particles of the same size as the oil film clearing cause the most harm.

Because tiny particles are more susceptible to ingress from the environment, oils have a high concentration of them. Sumps allow large particles to be screened and removed more readily. The first step in preventing particle-induced wear and failure is to keep dust out of the engine compartment.

Oil Filter Selection 101

When choosing an engine oil filter, there are various similar alternatives and considerations that must be traversed for the same reasons that it is vital to customize the selection of oil. These are the essential factors:

- Pressure-Flow

- Design and Fabrication Integrity

- Size and Capture Efficiency

- Dirt-Holding Capacity

Photo by: Machinery Lubrication

Photo by: Machinery Lubrication

Oil Filter Test Methods

To assess the performance of a motor oil filter in service, a variety of standardized test procedures are employed. SAE HS 806 and SAE J1858 are the two most frequently mentioned test standards for oil filter selection. Collapse strength, burst pressure, single-pass efficiency, dirt-holding capacity, pressure-flow profile are among the parameters evaluated. Many of the subparts of ISO 4548 are quite similar to these standards.

- Flow Resistance

- Filter Capacity and Dirt Removal

- Oil Filters Characteristics

- Particle Retention Capability Test

- Media Migration Test

- Collapse Test for Lube Oil Elements

- Inlet and Outlet Anti-Drain Valve Test

- Ability to Meet Environmental Conditions

- Installation and Removal

- Mechanical Tests

- Relief Valve Performance

In terms of performance comparisons between commercial filter replacements, the SAE J1858 standard is more applicable. The filter's Beta Ratio, dirt-holding capacity, and pressure-flow profile are all calculated. This testing process, unlike the previous SAE HS 806 standard, employs online automated optical particle counters.

While all the main oil filter manufacturers have conducted the SAE J1858 test on their vehicle filter products, finding information on the findings for individual oil filters can be challenging. Such information is rarely included in product packaging, which is where customers expect to find it.

Le Price Clean Oil Solutions

CJC® Filter Separators

CJC® Filter Separator is a filtration system that combines fine filtration with water separation all in one unit, with an integrated circulating pump. They are designed for use in applications containing hydraulic oil, diesel fuel, lubrication oil, etc., in which water ingress is a constant or recurrent problem.

CJC® Fine Filters

CJC® Fine Filter is an offline oil filtration solution with integrated circulating pumps for offline installation. The filters are recognized around the world as a highly efficient purification system for applications such as hydraulic oil, lubrication oil, gear oil, quenching oil, phosphate esters, and more.

Source: machinerylubrication.com