In an internal combustion engine, the lubrication process begins in the sump, often known as the oil pan. The oil is then pushed through a strainer by the oil pump, which removes bigger impurities from the fluid mass. After that, the oil passes through an oil filter.

Businesses lose a lot of money as a result of industrial fires and explosions, which cannot be quantified in dollars. The most prevalent cause of these mishaps is that managers and employees are oblivious of the hazards they confront on a regular basis at work.

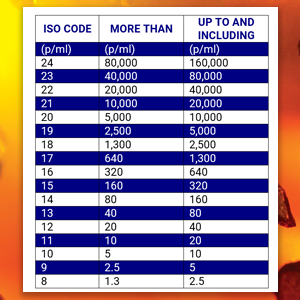

ISO Cleanliness Code is a three-digit number that is used to indicate particle contamination in oil. ISO 4406:99 is the worldwide standard for reporting contamination. Within a 1 ml sample, a laser is used to count particles of varying sizes, which are then reported in three numbers.

The potential for a significant financial gain via lubrication excellence is huge that most plants and industries in the Philippines have yet to realize. Reduced downtime as a result of avoiding breakdowns is the most prevalent financial advantage. In today's budgeting cycle and supply chain challenges, it pays to have better reliability and dependability. When you embark on your journey towards lubrication excellence, here are some useful tips to bear in mind to be able to capitalize on your programs.

Particle contamination is responsible for up to 80% of lubrication-related machinery failures. Particle ingress can lead to abrasion which generates wear debris. Increasing generation of wear debris warns any technician of approaching failure. A simple patch test allows technicians to discover the degree of severity of contamination in any system.