A single-point lubricator is a device that delivers a small amount of clean grease or lubricating oil to a specified region on a regular and automated basis. It is most commonly used to lubricate bearings, but it may also lubricate pumps, electric motors, fans, chains, and conveyors. Greasing bearings by hand frequently results in over-and under-greasing, resulting in premature bearing wear. In addition, automated lubrication allows proper lubrication of components that are too hard or risky to reach, which positively impacts reliability and safety.

The Different Types of Single-Point Lubricators and How They Work

Since the classic grease cup first appeared on the scene more than 30 years ago, single-point lubricator designs have advanced. Modern designs include features such as variable reservoir capacity, varied pressure and temperature limits, and multiple discharge rates ranging from weeks to months to a year or more. Let's look at five single-point lubricator designs to see whether they're right for you.

Single-point piston-activated lubricator:

A pressure generator, piston, liquid electrolyte, and lubrication chamber make up a single-point piston-activated lubricator. A pressure generator consists of a sealed plastic tube and a rubber bladder filled with an electrolyte solution. Inside the bladder, the electrolyte induces an electromechanical reaction that generates gas. The bladder is pressed against the piston by gas, and the piston then forces the lubricant into the bearing or component.

Spring-loaded grease cups:

Spring-loaded grease cups are a step above standard compression grease cups. It displaces grease via a spring-loaded plunger rather than a screw-down cap or piston. The consistency of the grease, as well as back pressure and temperature, impacts its flow. They come in sizes ranging from 2 to 18 ounces (60 to 532 cubic centimeters).

Precise-metering single-point lubricators:

Electric motors with particular relubrication quantity needs, as well as applications such as chains, gear racks, open gears, roller, and sliding bearings, and spindles, benefit from precision-metering lubricators.

Vibration-activated single-point lubricators:

Predetermined lubrication regimens (ranging from 15 days to 24 months) are possible with vibration-activated lubricators, although they only distribute grease or oil when the machine is running. These units come in three different sensitivity levels: low sensitivity for high-vibration applications, medium sensitivity for most ordinary machines, and high sensitivity for low-vibration applications. When a machine is idle, the vibration sensor detects it and switches the unit to pause mode, halting the lubricating cycle briefly.

Positive-displacement single-point lubricators:

The positive-displacement unit is one of the most recent designs of an electromechanical single-point lubricator. A reusable battery or direct-power motor, a refillable or replacement lubrication canister, and a follower plate are included with these lubricators. The lubricator can be programmed to dispense a certain amount of grease at a predetermined interval or to dispense the entire volume of grease over a specified time period.

High ambient temperatures soften grease, making it more fluid and increasing lubricator discharge pressure. Grease flow can also be aided by a low line restriction. For protection against high temperatures, spring-loaded lubricators are frequently manufactured of polycarbonate or borosilicate. Positive displacement lubricators have discharge pressures of 900 psi and regulate grease flow without resistance.

Single-point lubricators have a number of advantages.

Single-point lubricators are meant to distribute new grease or lubricating oil in a constant, metered, and continuous manner. When opposed to manual lubrication or other traditional lubrication methods, single-point lubricators provide a number of cost-cutting and efficiency-boosting benefits, such as the following:

- Over- and under-greasing can be reduced with controlled metered supply. This also improves bearing servicing, which boosts asset dependability.

- Once the lubricator is placed and configured, it is self-contained, which means no moving components or outside logistics are necessary. They're also simple to set up, keep up with, and troubleshoot.

- Because of their predictability, they may simply be incorporated into a maintenance plan to help with proactive maintenance.

- They are intended for flexible installation, so you may use direct or remote installation to position them in limited or dangerous places.

- Their automation, which makes them almost maintenance-free, saves maintenance hours, and decreases personnel expenses, typically results in a reduction in maintenance costs. You can not only cut down on maintenance time, but you can also cut down on human mistakes.

- Can be put in regions where greasing is required but is dangerous to access during routine machine operation.

Installation of a single-point lubricator

Single-point lubricators are intended to fit into bearing unit adapters quickly and simply. Make sure the volume/cartridge size dual in-line package (DIP) switch corresponds to the cartridge you're installing. Lubricators normally contain a reusable drive motor, which means you only have to change the lubricant cartridge and batteries once. Discharge durations often range from one to 24 months.

Remote Mounting: When you need to remove protective guards or safety cages to reach a lubrication point, the lube point is impossible or dangerous to access while the equipment is running, or the lube point is exposed to severe vibration and/or extreme temperatures, remote attachment is required. The following items are commonly seen in remote mounting kits:

- A conventional beam or cage bracket that may be clamped to a segment of the beam or used to square cage mesh using a cage hanger.

- You can purge the line, eliminate grease obstructions, and add extra grease via a purge connection with a manual valve.

- For each lubrication point, an angled fitting is available as an option.

- Each lubrication location has a push-lock hose connector.

- A heavy-duty hose with swivel hose ends that lock into place.

Direct Mounting: When you attach the lubricator directly into the bearing adapter, which was only briefly mentioned. This approach is best for lubrication places that have little shock loading and vibration, as well as lubrication points that are safe and easy to reach.

LPI Automated Lubrication Systems

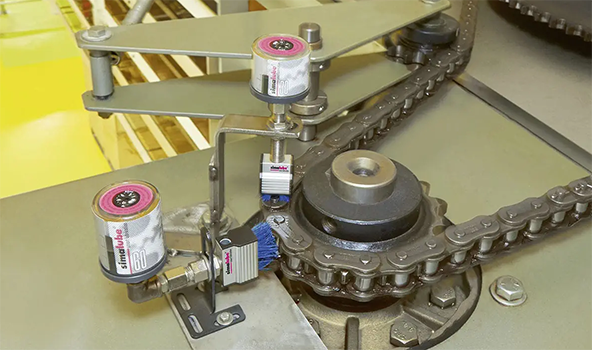

Simalube Multipoint

The simalube multipoint lubricator concurrently lubricates 5 points for up to a year in the same dependable manner as the other established simalube lubricators. When simalube multipoint runs out, it may be simply and rapidly changed thanks to the snap-on attachment.

Automating Lubrication Systems

simalube IMPULSE connect

The simalube IMPULSE connect is the latest generation of pressure booster from the simalube family. The proven functions of the IMPULSE have been supplemented with the option of connecting the device to a smartphone via Bluetooth®. In connection with the newly developed «simatec world of maintenance» app, the devices can be easily configured and then monitored without having to be directly located at the lubrication point. Information such as general status, fill level, lubricant, size, start, lube change date, etc. are displayed to the user and are easy to read in the app.

Automatic Riding Ring Lubrication

The quantity of lubrication required is reduced when it is applied precisely. The pump station, complete with the controller, is entirely preassembled, requiring minimal operator involvement. The spray impulses are controlled by a sensor that counts the gaps. The number of cycles may be adjusted, and the distance between the spray nozzle and the lubrication point can be up to 1 meter.

Source: machinerylubrication.com