Hydraulic systems monitoring and maintenance must improve to keep up with rising regulatory requirements and changing equipment design.

Source: machinerylubrication.com

Preconceptions

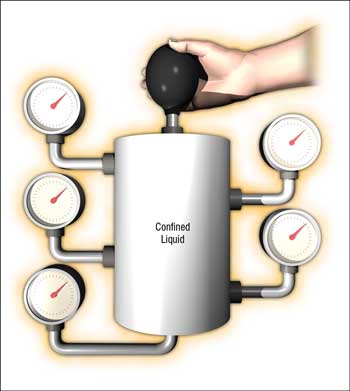

Hydraulic machinery is anticipated to be extremely dependable, with minimal downtime and low operating costs. Hydraulic systems must function with little equipment noise in order to provide a safe working environment. Hydraulic fluids must last longer while being cost-effective, despite these higher performance requirements.

Key Needs and Priorities of End-Users

A recent survey of end-users found three key needs regarding hydraulic fluids: productivity, extended equipment life, and reduced downtime. The survey also enabled the identification of the top operational problems end-users were experiencing with hydraulic valves. In many cases, slow or failed valve actuation means valves are routinely changed or cleaned, which costs time and money. Failure to respond to valve sticking can result in:

- Decreased production (most operators only respond when slow actuation is obvious)

- Unscheduled downtime

- Increased costs

- Safety concerns

Symptoms to Watch Out for During Hydraulic Routine Inspections

- Abnormal Noice - this is oftentimes due to cavitation that is happening in the system. When the aeration rate increases it will eventually lead to lubricant degradation, overheating, and seal damage. Look for the possible sources of aeration. Check whether the level of oil in the reservoir in the system is correct to avoid vortex formation. Inspect your pump's intake lines for issues. If the fittings and components are already worn out or looking abnormal, it's best to replace them.

- High Oil Temperature - overheating causes a number of issues in your machinery. It speeds up the degradation of your lubricant and it could lower the viscosity of your oil than the viscosity your components needed. The system could be losing its ability to dissipate heat. Remove any possible obstruction in the airflow around the reservoir. Inspect the condition of the heat exchanger. Inspect for possible aeration and cavitation and address the issue as soon as possible.

- Slow Operation - when there is a reduction in the performance of your hydraulic system, check for possible sources of leakage. Internal leakage can happen in the pumps, actuators, or valves. Internal leakage is signified by pressure drop. When pressure drops, heat generation can be observed. In this case, the use of infrared inspection tools is useful in detecting possible causes and locations of leakage.

Ways to Improve Performance and Prolong Lifespan of Hydraulic Systems

Control Contamination

Hydraulic systems are some of the most sensitive to contamination. Inspect if there is already a built-in filter in the system. If there is already a filter installed and you are still not achieving your target cleanliness, explore for a possible upgrade or revision of your target limit. Address possible locations of contamination regression such as reservoir headspace and cylinder rod surface.

Choose High-Quality Hydraulic Oil

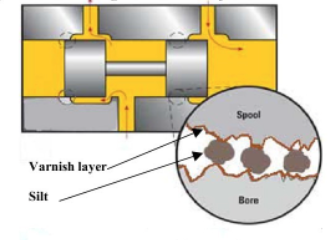

Hydraulic oils, like hydraulic equipment, are facing more difficult conditions. Higher temperatures, as well as higher oil pressures and shear rates, are unavoidable. As the fluid cycles quickly through the reservoir, it works harder and gets hotter, with less time to cool, release heat, and disperse foam. As a result, there is a propensity for degraded materials to build up in the system, which can lead to varnish and valve sticking.

When choosing the right lubricant for your hydraulic, do not only take into account what is written in your OEM manual; conduct research on the lubricant requirements specific to the type of application you have and weigh in the past accounts or experiences you had or other industry experts.

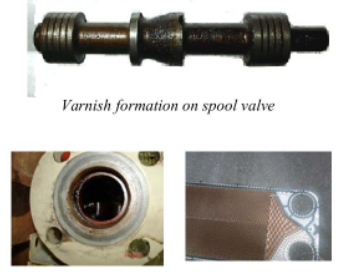

Address the Root Cause of Varnish Formation

Varnish develops as oil matures. Hydraulic fluid degrades due to oxidation and heat degradation, in addition to the natural process of additive consumption. A hydraulic fluid that does not leave varnish on surfaces is the ideal answer. Valve replacement would be reduced or eliminated as a result. Reduced valve sticking would not only improve operating economics but also benefit the environment by maximizing electricity usage and operational efficiency.

Source: Focuslab, Ltd.

Recommended Solutions for Hydraulic Application

CJC® Varnish Removal Unit

CJC® Varnish Removal Unit will typically reduce your varnish level relatively fast and within weeks your oil should show improved cleanliness. Depending on the size and initial degree of contamination, most pieces of machinery should improve their MPC levels in less than 1-2 months of operation.

Online Condition Monitoring

Valmet DNA Machine Monitoring provides process operators and maintenance employees with condition monitoring data through a single user interface. Operators can get important information from easy-to-understand user displays that help them maintain process performance. The same displays are available in the maintenance office, along with tools to assist maintenance personnel in analyzing complicated situations and isolating individual flaws.

Source: machinerylubrication.com