Be The First to Know

Stay ahead with the latest news, product launches, and expert tips. Sign up now and never miss an important update or opportunity!

-

Metering Device - 350

Series 350 single-line, pre-lubrication metering devices come in two, three, and five-port variants and are designed to be installed directly on the machine or system that requires lubrication. These metering devices were designed for use with single-line, centralized oil and fluid grease lubrication systems. By specifying the relevant order code, Series 350 metering devices can be supplied with main line fittings.

-

Metering Device - SL-V

The SL-V metering devices are designed for single-line, high-pressure centralized lubrication systems that dispense lubricants compatible with polyurethane seals up to NLGI 2.

-

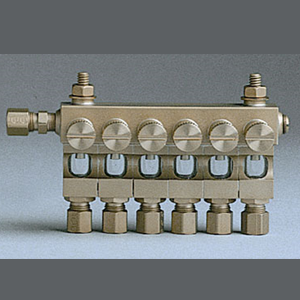

Metering Device - SLC

The SKF Lincoln SLC metering device is modular and intended for use in high-pressure single-line lubrication systems.

-

Metering Device SL-V XL

The high-output metering devices of the Series SL-V XL are designed for single-line, high-pressure lubrication systems that dispense lubricants compatible with polyurethane seals up to NLGI 2.

-

Pump Unit - 283167

Pump Unit - 283167 is a pneumatically driven oscillating positive displacement pump. The pump drive's change-over valve regulates the reciprocating of the pump strokes. The reciprocating pump runs under air pressure and releases material until the system oil pressure reaches the desired level. A pressure switch, 3/2 way air valve, and components to restrict and control the air operating pressure must be used to turn off and monitor the pump.

-

Pump Unit - 82570

Pump model 82570 is a high-volume pump with an air-powered forward stroke discharging lubricant. The acrylic reservoir is replenished using the strainer filling cap and has a check/relief valve to relieve pressure on the lubrication line.