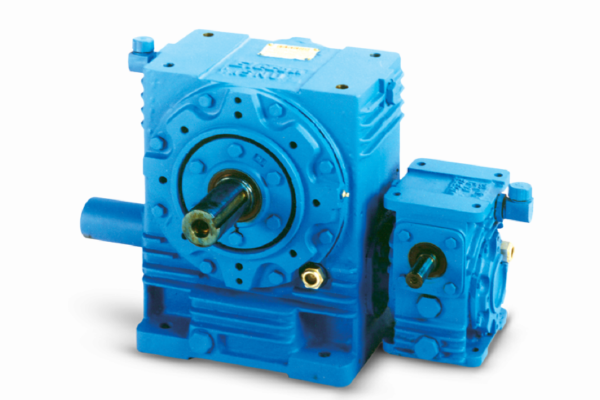

DESCRIPTION

The ELECON Double Reduction Worm Gear Units are built by combining two single reduction worm gear units. The initial worm gear unit is designed to be mounted directly onto a standard single worm gear unit, which serves as the secondary stage. This arrangement results in a compact and strong gear unit suitable for machinery that operates at slow speeds. A variety of ratios ranging from 75:1 to 4900:1 are offered, making these gear units ideal for applications requiring high torque and low speeds. The worm gearing adheres to the specifications of BS-721.

TECHNICAL SPECIFICATION

| Underdriven | SNU-UD / SFUD |

| Overdriven | SNU-OD / SFOD |

| Verticle output shaft | SNU-VD / SFVD ( UP/down ) |

| Hollow output shaft | SNU-SMD /SSMD |

| Sizes | 1¾/30, 2¼ /40, 2¼ /50, 3/60, 3/70, 4/80, 4/90, 5/105 , 5/120 , 6/140 , 7/170 |

| Ratio | Min. 75:1 to Max 4900:1 |

| Power Capacity | 50 kW |

APPLICATIONS

- Conveyors

- Raw Mill

- Coal Mill

- Nodulizer

- Elevator Drives

- Separator Drive

- Bulk Materials Handling

INDUSTRY

- Cement Industry

- Sugar Industry

- Steel Industry

- Power Industry

- Plastic Industry

- Chemical Industry

- Palm Oil Industry

- Rubber Industry

- Paper Industry