Machines ultimately fail because of wear and tear. You may not be able to stop it but you can delay it.

With the right maintenance technologies and practices, you will be able to predict it way before it happens. When you plan your maintenance activities, you can cut back on costs, and increase the productivity and safety of your plant. To put this in place effectively, here are the questions you must address according to Machinery Lubrication:

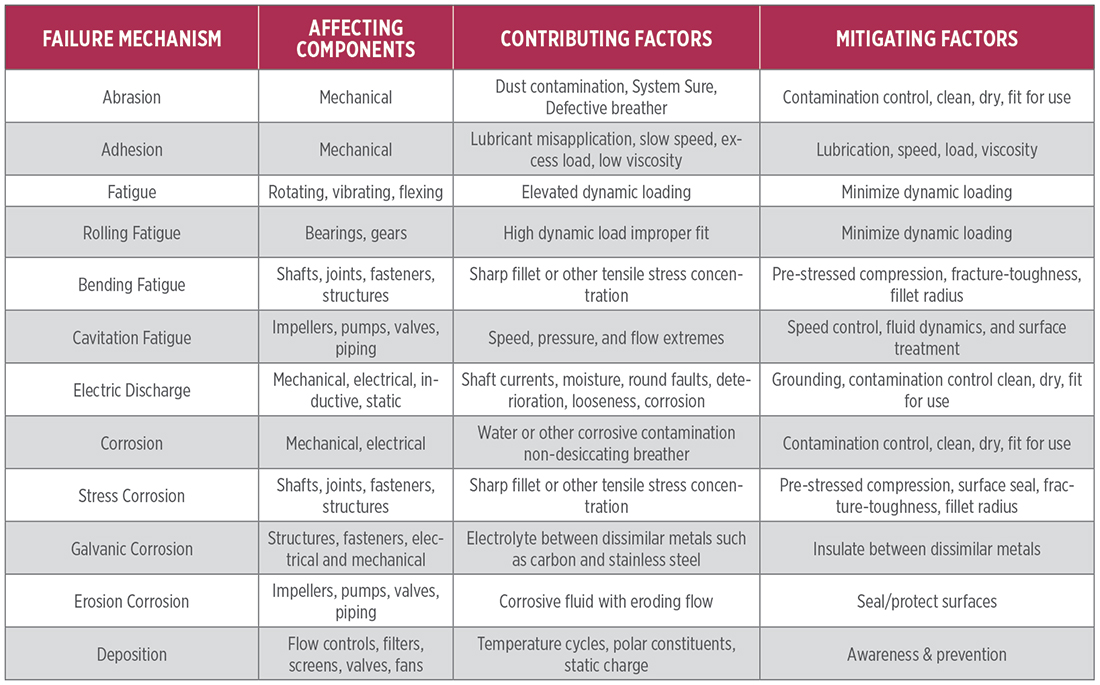

- Failure mechanisms

- Factors that exacerbate and accelerate failure

- Actions to reduce instances of failure

- Condition monitoring techniques to monitor the root causes of failure mechanisms and progression of incipient failures

Failure Mechanisms of Mechanical Machinery

Source: Machinery Lubrication

Source: Machinery Lubrication

Abrasion - Dirt and dust particles outside your system may enter and produce abrasive wear debris.

- Corrective Action: Implement contamination control program. Make sure that the breathers are effective and that you use proper lubricant dispensing tools. Explore the use of offline filtration systems if your system requires a higher level of cleanliness

- Inspection: Routinely check your filters and breathers to confirm if they are working and current. If you are not sure how to check or when to change them, contact our team to help you.

Adhesion - Adhesion is a frequent occurrence in all systems with loaded components such as gearboxes. Once adhesive wear starts generating, it propagates and accelerates other processes such as oxidation and corrosion. With metal-to-metal contact and compression, more heat is generated which speeds up the degradation of oil.

- Corrective Action: Use a lubricant that fits the requirement of your system. If your system requires the use of oil with EP additive, then do so. Always make sure that your system has the right level of lubricant and operational requirements (load and speed).

- Inspection: Check your system if it has adequate lubricant. Install an oil level gauge or sight glass to aid you in your routine inspection.

Rolling Fatigue - Rolling fatigue is commonly observed in bearings and gears where rolling contact happens that leads to microcracking and wear debris formation. Rolling Fatigue can be addressed by addressing imbalance issues and misalignment issues.

- Corrective Action: Conduct proper alignment using laser alignment tools for a more accurate measurement. Rolling fatigue is oftentimes triggered by improper bearing fit or when your system is operating at an abnormal temperature causing the components to expand. Use the right tools when installing your bearings and make sure that your system is properly lubricated.

- Inspection: Regularly check your system if the oil level is correct and conduct a vibration analysis check for misalignment and imbalance issues.

Source: Machinery Lubrication

Source: Machinery Lubrication

Cavitation Fatigue - Cavitation fatigue occurs when pressure, flow, and speed abnormally change. In cavitation fatigue, bubbles implode which produces supersonic surface impulses that lead to compression and shear stress causing metal surfaces to crack. Cavitation is commonly observed in impellers, pumps, or valves.

- Corrective Action - Cavitation issues can be addressed by correct fluid flow design, control, speed, and surface treatment.

- Inspection - Conduct routine oil analysis to check for air release. Also, employ IR inspection for hot spot detection as cavitation is usually accompanied by abnormal temperature increases.

Corrosion - Corrosion occurs when a corrosive substance corrodes the surface of metal changing its chemical nature into a soft, brittle metal oxide that can be easily scraped off the surface further exposing the components to oxidation. Corrosion can occur in electrical and mechanical systems and works synergistically with other failure mechanisms.

- Corrective Action - Address leak issues (coolant leaks) and moisture contamination ingression issues by installing a desiccant breather.

- Inspection - Conduct routine oil analysis to check for moisture, wrong oil contamination, or TAN levels.

Erosion - Erosion can occur when a surface that is already oxidized is routinely exposed to corrosive fluid with eroding flow.

- Corrective Action - To protect your system from erosion, address leak issues that could trigger corrosion as it has a synergistic effect on erosion.

- Inspection - Routinely check your impellers, pumps, valves, and piping. Install energy-absorbing coatings to protect the surfaces. Talk to our engineers to know how we can help you install a protective coating on your systems to prevent corrosion and erosion.

Deposition - Deposition results from the accumulation of foreign substances on a critical component such as varnish and fibrous materials. Varnish formation can result in stuck-up valves while fibrous material accumulation can lead to imbalance.

- Corrective Action - If your system is prone to varnish formation and contamination ingression, install a filtration system that specializes in the removal of varnish and other contaminants. Ensure that you conduct an oil change or partial drain and fill according to the result of your oil analysis. Prolonged use of degraded oil can worsen varnish issues.

- Inspection - Conduct routine oil analysis to monitor the level of contamination, degradation, and additive depletion of your oil. Consult a trusted third-party oil laboratory to help you identify the root cause of this issue.

Source: machinerylubrication.com