In modern industrial operations, machine efficiency and reliability are critical for maintaining productivity. A key aspect of ensuring machinery health is oil cleanliness.

Contaminated oil can lead to severe wear, costly breakdowns, and reduced lifespan of equipment. This is where advanced particle counters come into play—monitoring oil for contaminants like solid particles and water, and providing valuable insights for proactive maintenance. In this article, we'll dive into how these devices, such as the PAMAS S40 and the CJC® Oil Contamination Monitor OCM15, are transforming oil condition monitoring.

What Are Particle Counters and How Do They Work?

Particle counters are sophisticated instruments that measure and count solid particles suspended in oil or other fluids. They are essential tools in condition-based monitoring, helping industries track the health of their oils in real-time. These devices work by passing a fluid sample through a sensor, where particles are measured based on size and concentration. One of the most commonly used technologies in particle counters is the light blockage method, where particles obstruct a light beam, creating shadows that are detected and counted.

In oil analysis, such data is invaluable. Whether you’re monitoring hydraulic systems, gearboxes, or fuel lines, having access to real-time oil condition information allows for early detection of potential issues. This enables companies to take corrective action before small issues escalate into costly failures.

PAMAS S40: Excellence in Industrial Fluid Monitoring

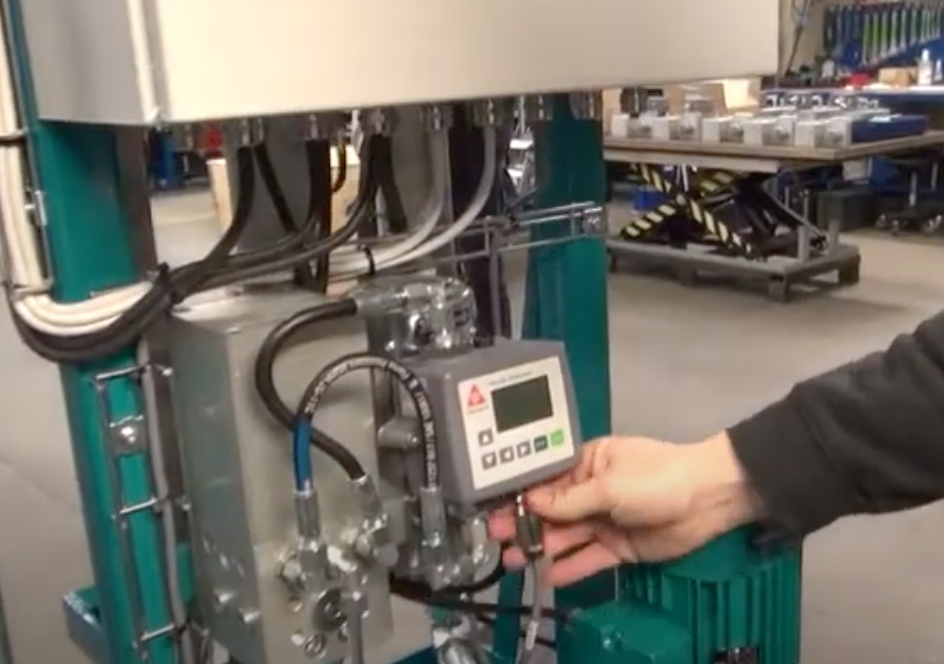

CJC® Oil Contamination Monitor OCM15: Early Warnings for Industrial Fluids

In industries such as manufacturing and energy, where heavy machinery operates under high stress, keeping hydraulic and lubricating oils clean is critical. The CJC® Oil Contamination Monitor OCM15 provides a proactive approach to oil condition monitoring. This advanced online particle counter is designed to track contaminants, including solid particles and water, providing early warnings before they cause significant damage.

The OCM15 offers several benefits, including:

- Earliest possible wear detection: This allows for condition-based maintenance, reducing the severity of failures and avoiding costly breakdowns.

- Accurate data: Unlike some counters, the OCM15 is designed to ignore air bubbles, ensuring precise measurements.

- Long-term ROI: By monitoring the smallest particles, the OCM15 prevents damage at an early stage, improving the overall performance and lifespan of machinery.

The device operates based on the ISO 4406 standard and can store up to 4,000 time-stamped data points. With USB connectivity for easy data export and analysis, operators can review historical data to understand long-term trends in oil cleanliness. Furthermore, the OCM15 is suitable for high-viscosity oils and fluids with large amounts of air bubbles, making it versatile across a range of industrial applications.

Why Oil Condition Monitoring Matters

Oil condition monitoring has evolved from a reactive approach to a proactive, data-driven practice. Tools like the PAMAS S40 and the CJC® OCM15 are vital in modern industries, where the cost of machine downtime or failure can be astronomical. By investing in particle counters, companies can not only reduce the risk of machine failure but also extend the operational life of their equipment.

In today’s competitive environment, condition-based maintenance offers a strategic advantage. Companies can minimize downtime, optimize resource use, and ultimately increase profitability by preventing failures before they occur. Monitoring oil cleanliness is a key part of this approach, and with real-time data from advanced particle counters, industries can stay ahead of potential problems.

Conclusion

The role of advanced particle counters in oil analysis and condition-based monitoring is more important than ever. Whether you're managing complex aviation systems with the PAMAS S40 or ensuring the health of industrial machinery with the CJC® Oil Contamination Monitor OCM15, these tools provide critical insights into the cleanliness of your fluids. Investing in such technology not only safeguards your equipment but also improves efficiency, reduces maintenance costs, and boosts profitability.

As industries continue to innovate, the demand for accurate, reliable oil monitoring will grow, making particle counters an indispensable asset in any operation focused on performance and longevity.