FEATURES

Planetary gearboxes offer a significantly higher mechanical rating when compared to parallel shaft gearboxes. This is because the power being transmitted is distributed equally among three to five streams in each stage, resulting in reduced induced stresses. As a result, the gearbox size can be optimized, and higher gear ratios can be accommodated, eliminating the need for open pairs.

Compared to conventional drives with open gearing, planetary gearboxes also offer a substantial reduction in floor space, with a potential decrease of around 50%.

The internal gears, such as the annuli, which are the heaviest gears, remain stationary in planetary gearboxes. As a result, they do not require bearings, leading to improved stability, reduced vibration levels, and subsequently lower noise levels. Achieving noise levels as low as 80-85 dB and vibration levels up to 4.5 mm/sec is possible.

By implementing direct drive and eliminating open gears, bearings, and couplings in the secondary gearbox, a power saving of 5 to 6% can be achieved. For instance, in a 45×90 mill with a power of 1100 kW, including the drive power of TRPF/GRPF, the savings can be equivalent to approximately 20% of the additional drive-related expenses. This means that the additional expenditure can be recovered within five seasons, leading to additional profit for the sugar industry.

One advantage of planetary gearboxes is that the planet bearings bear the load, while the bearings supporting the sun or carrier loads are effectively nullified due to the higher number of planets and their equal and opposite forces.

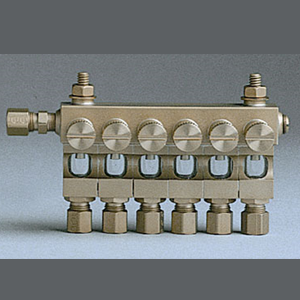

Lubricating a planetary gearbox is relatively simple since the rotating gear train partially acts as a pump, allowing for splash lubrication.

In our proposal, we suggest using a three-to five-stage planetary gearbox where the sun serves as the input and the carrier as the output. The annuli remain stationary, acting as the casing and are supported on a saddle as depicted in the drawing.

Elecon's machinery capability ensures that the internal teeth of the annulus are cut with accuracy according to DIN 7 standards. If required, grinding can be done to achieve accuracy class DIN 6.

INDUSTRY

- Sugar Industry