The bearing used in a machine influences how it should be maintained to ensure optimal equipment life. One of the most challenging difficulties confronting lubrication programs today is determining which bearing type is installed and about to be oiled.

Bearing Preparation

To lubricate a bearing, you must first know critical information about it. Many manuals provide exploded views or component lists that provide all the information you want. Bearings are often specified by standard numbers that define all specifications, allowing you to get a replacement bearing or establish suitable relubrication activities.

You may also see inboard and outboard bearings or input and output. This is a bearing that supports a shaft that runs through the piece of equipment. The motor's driving end is the shaft's side attached to the component. The fan side is denoted as the non-drive end. Thus, the side closest to the coupling is the inboard side, while the other is the outboard side.

Bearing Numbers

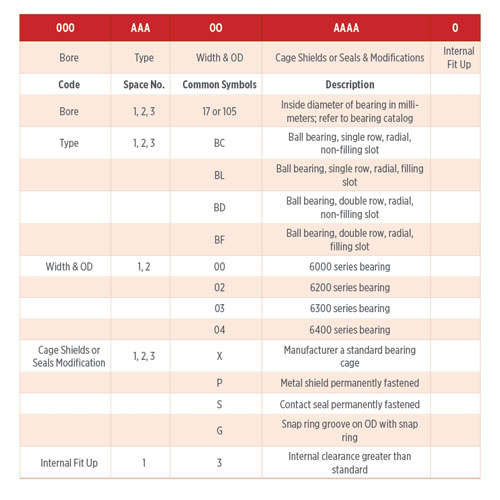

AFBMA Code System (Source: Noria)

AFBMA Code System (Source: Noria)

Following the discovery of the equipment tag and the bearing numbers, you will notice a succession of numbers and letters. This code is the key to unlocking the type of bearing used within the machine.

SKF bearings use the most used system. it utilizes a numeric code for the bearing's primary designation. A series of letters or numbers will also choose unique features.

The next designation is the Anti-Friction Bearing Manufacturers Association (AFBMA) code system. It has similar components in that it utilizes an alphanumeric system to state the bearing's dimensions and configurations. The code starts with the bearing's bore, followed by the type, width, outside diameter, and any modifications, such as seals or shields. Both of these systems can be cross-referenced against each other.

Identifying these numbers will be most important when you are performing greasing or vibration data calculations. They can also be helpful when your equipment needs to be repaired, and you want to replace a bearing with the same style or type.

Maintenance and Repair

You may opt to do maintenance and repairs in-house, depending on the type of equipment. This can offer better control over which replacement parts are selected and installed before the machine is placed back into service. While the exact size bearing is put back into service, the bearing's configuration may change. Using a bearing not stated on the equipment tag might lead to a maintenance-induced failure.

Over time, the grease can build up, cause a failure, or contribute to a failure mechanism due to increased heat or drag. Thus, whenever the replaced bearings are different from those installed, every effort should be made to document this in the Computerized Maintenance Management System (CMMS) or on the equipment.

If you replace a bearing with one that doesn't need periodic relubrication, you can ensure greasing will not create an issue by replacing the grease fittings and by installing an automatic lubrication system that ensures your bearing components are lubricated with just the right amount at the right time. This can be achieved during a repair. Not only will this reduce the risk of someone applying grease where it isn't needed, but in-house and contracted teams can also use it.

Finally, adequate contamination control systems improve machine performance and reliability and extend component life while lowering operation and maintenance costs. Keep your bearing clean with Le Price International's contamination control solutions.

Source:

Cash, W. (n.d.). Understanding Your Bearings Prior to Lubrication. MachineryLubrication. Retrieved from https://www.machinerylubrication.com/Read/31497/%20understanding-bearing-lubrication/