For years, economists and employees alike have theorized about the economic effects of automation.

While the manufacturing industry has experienced radical change with the onset of automation, some types of automation still look very different from the robot takeover some have feared.

To be competitive, businesses must keep ahead of the technology curve and ensure their employees have the skills to be effective in an automated world.

Pros

Automation may help intelligent businesses boost their bottom line in various ways. It is crucial for a speedy and accurate process. Your workflow and other details are safe using a cloud-based management system. There is, at most, security in maintenance software. With advanced technology, automation will be done within hours. It is a simple procedure that will take several days.

It has proven important for keeping businesses on schedule throughout the COVID-19 pandemic, despite supply chain delays, remote work, and several other hurdles. Here are a few more significant benefits:

Consistent Outputs

When tasks like sending lead-generation emails or tracking inventory are automated and set to run at regular intervals, businesses remove human delays and disruptions from the equation. The predictability of automation allows companies to plan better and expect challenges and opportunities rather than being blindsided by them.

Employee Engagement

Few individuals love repetitious duties. Automating those tasks can free up employees' time to focus on innovative, value-added work that can only be done by a human and that many find more satisfying.

Fewer Errors

Whether automation is handling a simple task or conducting complex financial projections, it can reduce the potential for errors if configured. After all, computers aren't distracted like humans. Plus, when employees can access data and workflows through a centralized process, they likely avoid miscommunication and work duplication.

Growth

Certain types of automation allow businesses to reach more customers without extra team member input. That means they can grow and scale their business with lower associated operating costs since fewer other workers are needed to complete manual processes.

Cons

While automation has many pros, it has its cons. Challenges posed by automation include the following:

Cost

While automation can yield considerable benefits, it is critical to consider the upfront expenses when assessing prospective ROI. Businesses that need customized solutions can expect to pay an extra premium. These capital expenditures can be a challenge for companies to overcome if they are already operating on tight margins.

Utilizing automated machinery in a manufacturing plant requires a high, sunken operational cost. Making the transition can cost thousands and millions of dollars, depending on the type of manufacturing plant.

Inflexibility

While today's automation technology can be tailored to suit specific business needs, there's no denying that it removes a human touch from the equation.

Need for Training

Employees will need significant upskilling and reskilling as automation takes over certain activities and alters the kinds of professions in demand. Furthermore, the need for soft talents that technology cannot replicate will increase.

Automation in manufacturing hasn't been implemented until very recently. There is a world of unpredictable costs and challenges that come with new technology.

Lube Accessories

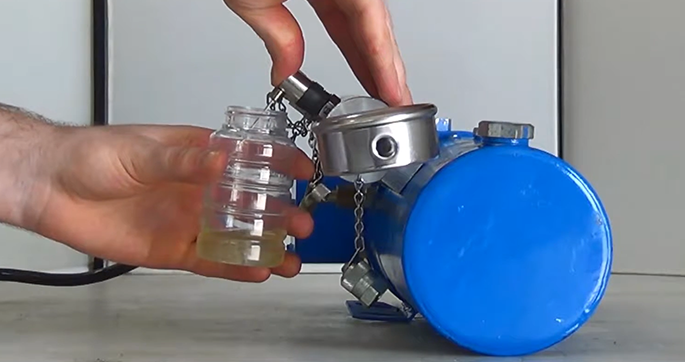

Finish your lubrication with the appropriate fittings and accessories. The LP Series from Le Price International allows you to conduct sampling in low-pressure systems at the push of a button. It's perfect for testing high-viscosity oils ranging from 3 to 125 psi. It is also suitable for lower viscosity oils at low return line pressures, approximately 3 to 50 psi.

Checkfluid KP Pushbutton

Checkfluid KP Pushbutton

Other accessories from Le Price that can help you fulfill specific lubrication tasks include Oil Sample Ports, KST Series (Pressurized), Standard Flow Oil Sampling Kit, and more.

Condition-based Monitoring

As the Industrial Internet of Things (IIoT) continues to help simplify the path to condition-based monitoring (CBM), Le Price International’s CBM program is your ultimate partner for predictive maintenance.

UE Systems 4Cast

UE Systems 4Cast

With only one touch, you may perform spectrum analysis, record, snap photographs, and take temperature measurements using our Ultraprobe® 15,000. We also offer Easy-Laser XT770, which lets you perform shaft alignment of mounted machines and align machine trains with an unlimited number of machines.

Sources:

3 Major Advantages of Automation in Preventive Maintenance. Innomaint. (n.d.). Retrieved from https://www.innomaint.com/blog/3-major-advantages-of-automation-in-preventive-maintenance/

Hastings, R. (2021, November 4). The Pros and Cons of Automation in the Workplace. Emeritus. Retrieved from https://emeritus.org/blog/pros-and-cons-of-automation-in-the-workplace/

Kornak, A., & Steblay, J. (2018, November 6). IIoT helps simplify the path to CBM. Fluke Accelix. Retrieved from https://www.accelix.com/iiot-simplifies-cbm/

PROS AND CONS OF AUTOMATION IN MANUFACTURING. CraftForce. (n.d.). Retrieved from https://www.craftforce.com/pros-cons-automation-manufacturing/