According to Machinery Lubrication, about 60% - 80% of bearing failure is due to improper lubrication.

Improper lubrication may include excessive application of lubricant, the use of mixed or wrong lubricant, and so on. Although some bearings are expensive, the cost of a newly purchased bearing is often insignificant when compared to the lost output and the cost of repairing the damage.

Many bearings are still manually lubricated. It is a challenging job, no matter how diligently a maintenance worker follows a lubrication plan. Since workers are required to handle various tasks today in plants' tight environments. Therefore, proper lubrication is often overlooked.

Why Use Automatic Lubrication System

Le Price Simalube Multipoint can supply five lubrication points up to one year

Proper maintenance of any bearing requires proper lubrication. Replacement of bearings, labor for replacements and repairs, excess lubricant, and labor for inefficient manual practice are some of the direct costs associated with improper lubrication. Downtime or missed production are some of the indirect, but very real costs. Other sources of wastage could be due to product spoilage caused by excess lubricant, environmental issue, safety, housekeeping issues, and excessive energy consumption.

Le Price Simalube 15 mL is an ideal choice for components in tight spaces

Although grease guns and manual lubrication appear to suffice for certain maintenance tasks, their advantages in terms of efficiency, environmental concerns, and worker protection frequently pale in comparison to those offered by an automated lubrication device. By delivering the right amount of the right lubricant to the right location at the right time, an automated lubrication device does not only address bearing failure but also solves issues with lubricant waste, safety, and environmental problems.

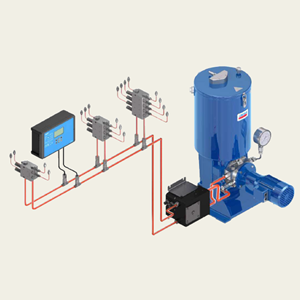

Le Price Lincoln Dual-Line System is a good choice for large machinery exposed to harsh conditions

Right Time

The main difference between automatic and manual lubrication is that technicians prefer to lubricate manually on a schedule rather than when the bearing requires it. To compensate, the operator will always fill the bearing until the lubricant begins to seep out. By the time the operator returns to it, the lubricant might have been essentially wasted. This can either lead to over lubrication or under lubrication. Automated lubrication, on the other hand, continuously delivers the right amount of lubricant to the bearing, allowing it to perform at its best. It also helps to seal the bearing from pollutants when it is properly lubricated in this manner.

Right Amount

Automated lubrication is more accurate and removes the bearing failure cycle of over lubrication and under lubrication. Excess lubricant is therefore prevented from leaking into the finished product, the floor, or other work surfaces. As a result, there are fewer rejections, cleanup and disposal issues, and lubricant waste.

Safe Work Environment

Worker protection is another advantage of an automatic lubrication device. It is no longer possible for workers to manually apply lubricant when machinery is running in dangerous and difficult-to-reach areas.

When to switch to Automatic Lubricators

Small amounts of grease applied at short intervals are theoretically superior to large amounts of grease applied at long intervals. When applying grease manually, the aim is to add as much grease as possible without causing damage due to over-greasing. Although this is good for the majority of grease-lubricated components, there are a number of applications that would benefit from more regular application and exact volumes. Of course, you might simply lubricate these components on a regular basis, but the associated labor cost would likely make automatic lubricators a more appealing choice.

Points to consider before switching to Automatic Lubricators:

- Check how much grease should be supplied to the machine on a regular basis by checking oil viscosity at operating temperature, calculating the volume required for every lubrication activity, and calculating the the frequency of greasing activity

- Confirm if your manual lubricator dispenses the correct volume over time

- Confirm if your lubricant or grease is suitable for use given the ambient temperature and environment

- Confirm the level of performance of your critical equipment through routine inspection to determine if your current practice works and does not need changing

When choosing which among your lubricated components need an automatic lubrication system requires information such as the factors that cause regular re-lubrication, such as high speeds, the type of environment, the level of contamination.

Factors That Lead to Frequent Lubricant Application

Temperature

Some bearings may need to be lubricated every day or even every few hours in high-temperature applications. In this case, it would require a small army of technicians to complete the task of manual re-lubrication of hundreds of bearings everyday which makes automated application a logical choice.

High Speed

High-speed bearings can be very sensitive; they often require constant grease application but they can easily get damaged by overapplication leading to overheating or skidding.

Contamination

Contamination is also the most significant contributor to grease reapplication requirements. When contamination is serious, any application will require very frequent application, regardless of other factors.

Source: machinerylubrication.com