Lubrication professionals need both the tools and knowledge to conduct oil sampling properly.

These two factors come hand in hand to ensure a successful and reliable analysis of the condition of your machine. It will cost far less to use the right oil sampling equipment than to utilize the unmodified set-up that gives you garbage data.

Proper oil sampling tools also protect your machine from being exposed to elements such as water, ambient air, and foreign particles. These elements might get into your system causing further damage to your machines. Sampling the oil can be done safely and effectively with the use of oil sampling equipment.

Poor Oil Sampling Practices

1. Bottom Sampling - Samples taken from the bottom of the tanks will yield a higher concentration of bottom sediments. For accurate Oil sampling results, you should avoid taking samples at the bottom of the tank.

2. Reservoir Sampling - Taking samples from turbulent tank and reservoir zones will only give you accurate data on oil condition, but not contamination and wear conditions. In the reservoir, the severity of wear metals and contaminants might become hidden by dilution.

3. Upstream Sampling - Taking samples on the feed-line of oil circulating systems results in getting a false negative result. Actual concentrations of contaminants and wear metal are often unseen in the oil sampling process.

4. Downstream Filter Sampling - Downstream filter sampling does not fully capture particles that are the size filters typically remove. This sampling method prioritizes sampling convenience over accuracy which can give a false-negative result.

5. Dead-Zone Sampling - Using a sample taken from a dead zone is useless and inefficient. Samples taken from a dead zone have properties that are different from working fluids.

6. Wrong-Procedure Sampling - Inadequate flushing and dirty sample hardware are examples of the commonly used sampling tools. These tools can be used consistently, but the results will not be accurate. Using these methods can save time, giving up accurate data.

7. Cold-System Sampling - Collecting samples from cold systems will show different concentrations of wear metals, contaminants, and other insoluble elements. Always remember that consistency can not ensure the quality of a sample. Gathering data from invalid oil samples will never show you accurate data. Correct sampling location, sampling procedure, and consistency are needed to conduct a successful Oil Sampling.

Tools and Solutions

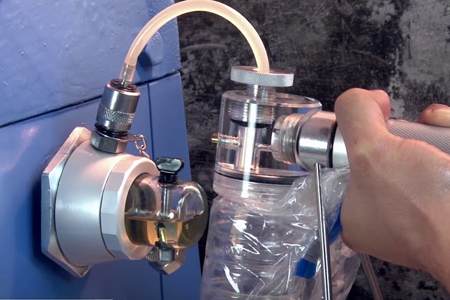

Oil sample ports come with protective cap seals to prevent contamination. The cap is connected to the sample port with a brass chain to prevent loss. With a properly installed sampling port, you can acquire samples directly from lubricating oil while your machine is running. Sampling ports are adaptable to pressure, static, and vacuum locations. You can consult with Le Price reliability engineers on how to install sampling ports properly.

You can use the V Series Valves with full flow dispensers to control the feed rate at the point of lubrication. The V Series Valves have 1 to 6 outlets that can be easily cleaned when needed. The V Series Valves are made of acrylic and heat-resistant glass that allows easy automation of drip-rate. The horizontal design of the needles helps protect the valve seat from contamination.

This tube takes oil from the valve to the sample bottle. A microbore tubing is needed for more accurate sampling.

Vacuum pumps extract oil samples together with a flexible extraction tube to pull the fluid sample to the sample bottle.

Oil Sample Bottles

In choosing sample bottles, you need to take into consideration the application and planned oil test. Always consider the size, cleanliness, and material from which the bottle was made.

Following the proper sampling procedures will surely yield accurate and useful data. To keep your oil protected from contaminants, you can install breathers, filtration systems, and other clean oil solutions.

Source: machinerylubrication.com